A Guide to FCAW Flux Core Arc Welding: How It Works Best Practices Wire Types and Common Applications

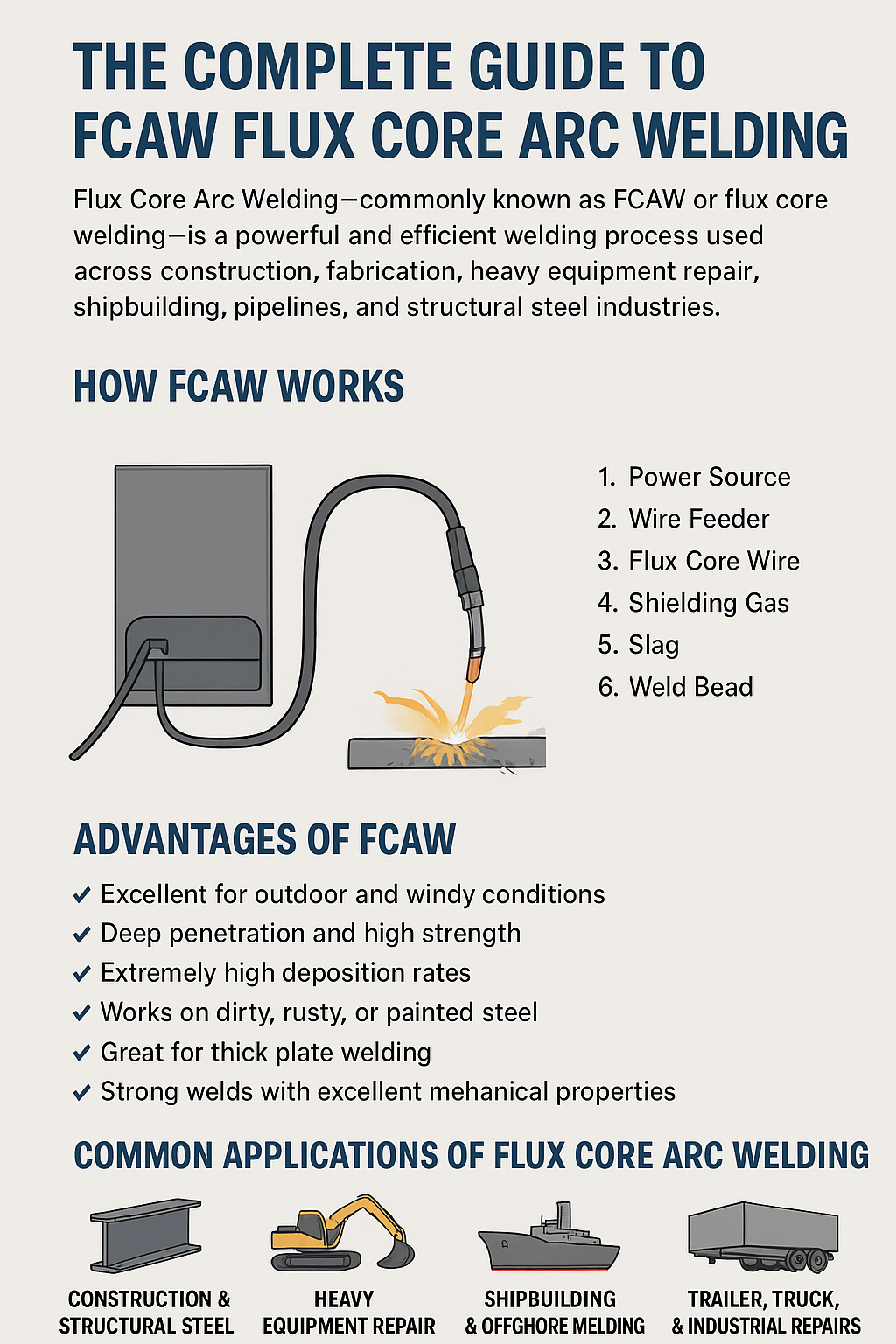

Flux Core Arc Welding—commonly known as FCAW or flux core welding—is one of the most powerful and efficient welding processes used across construction, fabrication, heavy equipment repair, shipbuilding, pipelines, and structural steel industries. Known for its high penetration, deep fusion, and ability to weld outdoors in windy conditions, FCAW is a top choice for welders who demand strong, durable welds even in challenging environments.

In this comprehensive guide, we break down everything you need to know about FCAW, including how the process works, the different types of flux-core wire, ideal applications, machine setup, and best practices used by certified red seal welding professionals.

What Is FCAW (Flux Core Arc Welding)?

Flux Core Arc Welding (FCAW) is a semi-automatic welding process that uses a continuously fed consumable wire containing a flux compound in its core. The flux reacts under heat to create shielding gases and slag, protecting the weld from contamination.

FCAW is similar to MIG welding, except FCAW uses flux-filled wire instead of solid wire and can be used with or without external shielding gas:

FCAW-S (Self-Shielded)

FCAW-S (Self-Shielded)

- No external gas tank needed

- Ideal for outdoor, windy, and mobile welding

- Strong penetration for structural work

FCAW-G (Gas-Shielded)

FCAW-G (Gas-Shielded)

- Uses external shielding gas

- Produces cleaner welds with less spatter

- Preferred for indoor fabrication and manufacturing

This flexibility makes FCAW one of the most versatile welding processes in heavy-duty industries.

How Flux Core Welding Works

The FCAW welding system includes:

1. Power Source

Most FCAW uses DC Electrode Negative (DC-) for self-shielded wire and DC Electrode Positive (DC+) for gas-shielded wire.

DC- provides deeper penetration for structural applications.

DC+ offers smoother welds and stable arcs.

2. Wire Feeder

A motorized feeder pushes flux core wire at a controlled speed, acting as both:

- The welding electrode

- The filler metal

Wire feed speed determines weld deposition and penetration.

3. Flux Core Wire

The wire has a hollow center filled with flux that provides:

- Shielding gas

- Slag formation

- Arc stabilization

- Alloying elements

- Enhanced weld strength

The flux is the key difference between FCAW and MIG welding.

4. Shielding Gas (For FCAW-G Only)

Common gases include:

- 100% CO₂ → Deep penetration

- 75/25 Argon-CO₂ → Cleaner welds, reduced spatter

- 90/10 Argon-CO₂ (Dual-Shield) → High-performance structural welding

5. Slag Formation

As the weld cools, slag forms on top of the weld bead.

Slag protects the molten weld and must be removed afterward.

Advantages of FCAW Welding

FCAW is popular because it offers benefits unmatched by other processes:

Excellent for Outdoor and Windy Conditions

Excellent for Outdoor and Windy Conditions

Self-shielded wire produces its own gas cloud—a major advantage over MIG.

Deep Penetration and High Strength

Deep Penetration and High Strength

Ideal for structural steel, bridges, heavy equipment, and thick materials.

Extremely High Deposition Rates

Extremely High Deposition Rates

FCAW can deposit metal faster than MIG and Stick, increasing productivity.

Works on Dirty, Rusty, or Painted Steel

Works on Dirty, Rusty, or Painted Steel

Flux cleans impurities and ensures strong fusion.

Great for Thick Plate Welding

Great for Thick Plate Welding

FCAW is commonly used on materials from 3/16″ to 1″ or thicker.

Strong Welds with Excellent Mechanical Properties

Strong Welds with Excellent Mechanical Properties

Perfect for critical welding applications.

Common Flux Core Welding Wire Types

Choosing the correct wire ensures proper weld strength and quality. The most common FCAW wires include:

1. E71T-11 (Self-Shielded)

Most popular FCAW-S wire.

Benefits:

- No gas required

- Great for outdoor welding

- Good penetration

- Works in all positions

Used widely for construction welding, general repairs, and farm equipment.

2. E71T-1 (Gas-Shielded “Dual Shield”)

Professional-grade FCAW-G wire for structural fabrication.

Benefits:

- High deposition rates

- Clean, strong welds

- Minimal spatter

- Excellent mechanical properties

Common in fabrication shops, shipbuilding, and heavy steel assembly.

3. E71T-8 (Structural Self-Shielded Wire)

Designed for:

- Thick structural steel

- Bridges

- High-rise construction

- Welds requiring deep penetration

Provides exceptional strength and reliability.

4. E70T-4

Used for:

- Heavy equipment rebuilding

- Industrial fabrication

- Deep joint penetration

Strong, extremely durable welds but not aesthetically focused.

5. Specialty Wires

- Stainless steel flux core wire

- Hardfacing flux core wire

- Nickel-alloy flux core wire

Used for specialty applications like corrosion resistance or abrasion control.

Best Practices for FCAW Welding

For clean, strong welds, welders follow these proven techniques.

1. Maintain Correct Stick-Out

Flux core stick-out should be 5/8″ to 3/4″ for FCAW-S.

Too long → weak arc and porosity

Too short → excessive heat and spatter

2. Use Proper Travel Angle

Most FCAW uses a drag (pull) technique at a 10–15° angle.

Dragging keeps the slag behind the puddle to reduce contamination.

3. Select the Right Wire Feed Speed

Wire feed controls penetration.

Increase if:

- Arc is sputtering

- Wire is burning back

- Weld is sitting too high

Reduce if:

- Too much spatter

- Burn-through occurs

- Over-penetration appears

4. Adjust Voltage Correctly

Voltage controls arc length.

- Too high: flat, wide beads

- Too low: narrow, unstable arc

Correct voltage produces a smooth, steady buzzing arc.

5. Clean the Base Metal When Possible

Even though flux core tolerates dirt, performance improves by removing:

- Rust

- Oil

- Paint

- Moisture

6. Avoid Overheating the Weld Area

Flux core welding runs hot—be mindful to prevent:

- Excess warping

- Burn-through

- Excessive slag inclusion

7. Remove Slag Between Passes

Slag must be removed with:

- A chipping hammer

- A wire brush

- A grinder (when necessary)

Slag left behind leads to porosity, inclusions, and weak welds.

8. Keep Your Machine and Consumables Clean

- Change contact tips regularly

- Clean drive rollers

- Replace worn liners

- Use knurled rollers for flux-core wire

Good maintenance ensures reliable feeding and stable arc performance.

Common Applications of Flux Core Arc Welding

FCAW is used in some of the world’s toughest industries due to its penetrating power and outdoor capabilities.

1. Welding for Construction & Structural Steel

1. Welding for Construction & Structural Steel

FCAW is the dominant process for:

- High-rise buildings

- Bridges

- Support beams

- Columns and girders

- Heavy structural connections

E71T-8 and E71T-1 wires are standard for structural codes.

2. Heavy Equipment Repair

2. Heavy Equipment Repair

Flux core welds are tough and durable—perfect for:

- Excavator buckets

- Bulldozer blades

- Loader arms

- Wear plates

- Cracked frames

Hardfacing flux core wire adds wear resistance.

3. Shipbuilding & Offshore Welding

3. Shipbuilding & Offshore Welding

FCAW is common for:

- Hull assembly

- Deck structures

- Marine-grade steel

Gas-shielded FCAW-G is preferred for its reliability.

4. Trailer, Truck, & Industrial Repairs

4. Trailer, Truck, & Industrial Repairs

Used for:

- Box frames

- Industrial trailers

- Steel decks

- Structural reinforcements

Self-shielded wire handles outdoor repair environments easily.

5. Welding and Fabrication Shops

5. Welding and Fabrication Shops

Dual-shield FCAW-G is the top choice for fabrication because it produces:

- Clean welds

- High deposition

- Strong mechanical properties

Ideal for large-scale production welding.

6. Manufacturing & Production

6. Manufacturing & Production

Robotics and automated welding frequently use FCAW-G for large volume output.

Why FCAW Is a Professional Welder’s Go-To Process

Flux core welding offers:

- Exceptional strength

- Fast deposition rates

- Reliability in bad weather

- Ability to weld thicker materials

- Superior penetration

It’s the ideal combination of power, durability, productivity, and versatility—making FCAW one of the most relied-on welding processes in industrial environments.

Final Thoughts: FCAW Remains One of the Strongest and Most Reliable Welding Methods

Whether used on construction sites, in manufacturing facilities, or in heavy equipment repair, Flux Core Arc Welding delivers unmatched performance and strength. Its ability to handle dirty metal, weld outdoors, and penetrate thick steel makes it indispensable to welders who need results that last.

The post A Guide to FCAW Flux Core Arc Welding: How It Works, Best Practices, Wire Types, and Common Applications first appeared on fabricationpros.ca.

via fabricationpros.ca fabricationpros.ca/a-guide-...